The world of the automotive industry is a wonderful and complex gear in constant motion. Building a car is a process that involves multiple stages, from initial design to delivery of the vehicle to the customer. At each of these stages, quality control plays a vital role in ensuring that the cars that hit the roads are safe, reliable and efficient.

In design and planning:

The quality of a car begins with its design and planning. In this initial stage, technical specifications are established, materials are selected and manufacturing processes are defined. Quality control here involves evaluating the suitability of materials, checking tolerances, and identifying potential manufacturing problems. A well-thought-out design with proper quality controls lays the foundation for a successful vehicle.

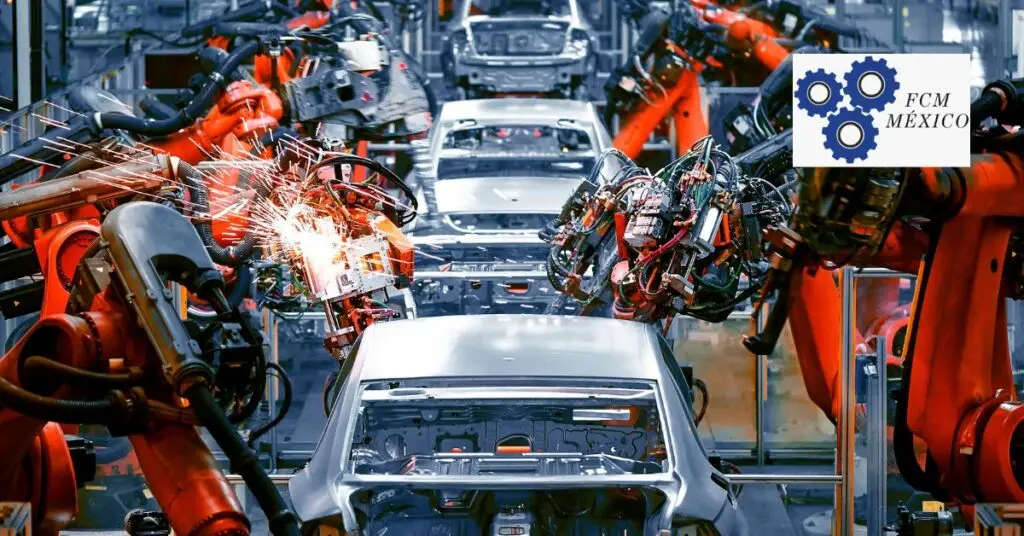

ANDn production:

The production stage is where a car comes to life. From casting parts to final assembly, each step must be meticulously controlled. In-line testing, visual inspection and specification verification are essential to detect defects and ensure each component fits perfectly. Quality control in this phase ensures that cars are consistent and meet safety and performance standards.

In testing and validation:

After production, cars must undergo rigorous testing and validation. This includes safety testing, performance testing, emissions testing and much more. Quality control at this stage ensures that each vehicle is ready to face the demands of the real world. Any problems detected are addressed before the car reaches the hands of consumers.

QA in after-sales service:

The relationship between quality control and customer satisfaction does not end with the delivery of the car. The automotive industry also benefits from quality control in after-sales service. Monitoring durability and performance over time, along with complaint management, contributes to a brand's reputation and the well-being of its customers.

Conclusion:

In summary, quality control is a fundamental pillar in the automotive industry. From design to after-sales service, it ensures that cars are safe, reliable and efficient. In a world where safety and quality are paramount, automotive quality control is the key to excellence in automotive manufacturing. Being an expert in the industry, I can confidently say that quality will always be the way to go in car building.